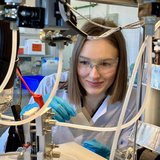

Research

The ICVT's research projects deal with the production and characterization of porous systems (catalysts, electrodes), the development of new geometries of catalytically active materials, the determination of kinetic data of chemical and electrochemical reactions and the design of reaction apparatuses, taking into account the coupling of transport and reaction processes. In addition to the experimental investigation of materials and reactions, the development of mathematical models and suitable simulation strategies is playing an increasingly important role.